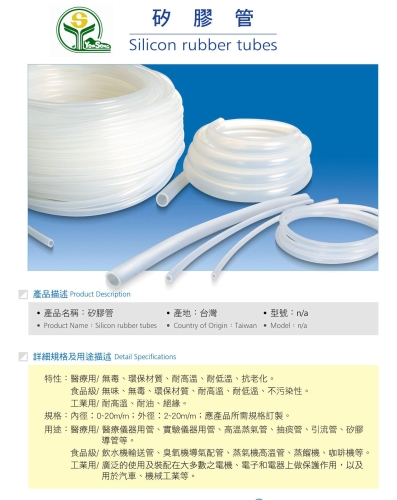

矽膠套管

矽膠套管 矽膠套管(Silicone Tubing)是由矽膠材料製成的管狀產品,具有彈性、耐用和耐高溫等特點。矽膠套管在各個行業和應用中廣泛使用。以下是關於矽膠套管的更多信息:

矽膠套管 矽膠套管(Silicone Tubing)是由矽膠材料製成的管狀產品,具有彈性、耐用和耐高溫等特點。矽膠套管在各個行業和應用中廣泛使用。以下是關於矽膠套管的更多信息:

特點:

耐高溫性:矽膠套管具有出色的耐高溫特性,通常可耐受高達200°C的溫度,並能在高溫環境中長時間使用而不變質或變形。

彈性和柔韌性:矽膠套管具有良好的彈性和柔韌性,能夠扭曲、壓縮和拉伸,並在應力消除後迅速恢復原狀,不易破裂或斷裂。

耐化學性:矽膠套管具有優異的耐化學性能,能夠抵抗許多化學物質,包括酸、鹼、溶劑和油等,不易受到腐蝕或損壞。

絕緣性能:矽膠套管具有優異的絕緣特性,能夠有效隔離電流,用於電子和電氣設備中,提供絕緣和保護效果。

應用:

食品和飲料行業:矽膠套管常用於食品和飲料加工和處理中,如輸送飲品、液體或氣體,以及作為飲水機、咖啡機和飲料分配系統的管道。

醫療和生命科學:矽膠套管廣泛應用於醫療器械、醫療設備和生命科學研究中,如導管、輸液系統、生物反應器等,提供耐藥性、生物相容性和高溫耐受性。

工業和自動化:矽膠套管在工業領域中用於各種流體傳輸、氣體輸送、真空應用等,同時用於自動化系統中的管道和連接件。

電子和電氣:矽膠套管可用於電子和電氣設備中的絕緣和保護應用,如電線、電纜的包覆、絕緣管和電子元件的保護套。

矽膠套管的規格可以根據具體應用需求進行定制,包括內徑、外徑、厚度和長度等參數。常見的內徑範圍從細微的尺寸到數十毫米不等,外徑和厚度也會根據需要進行設計。製造商可以根據客戶的需求提供符合應用要求的矽膠套管。

矽膠套管在不同應用中具有多種特點和優勢。以下是進一步的資訊:

飲水器材和咖啡機:矽膠套管常用於飲水機、咖啡機等設備中的輸水管道。由於矽膠材料具有耐高溫和耐化學性,能夠確保飲水器材的安全性和耐用性。

真空應用:矽膠套管由於其良好的彈性和密封性能,常用於真空應用中,如真空輸送管道、真空封裝和真空吸盤等。它們能夠有效地保持真空壓力,達到良好的密封效果。

高精度液體輸送:矽膠套管通常具有光滑的內壁,能夠確保高精度的液體輸送。它們在藥品配藥、化學實驗和液體分析等領域中得到廣泛應用。

汽車和交通工具:矽膠套管可用於汽車和其他交通工具的冷卻系統、空調系統和燃料系統等應用中。它們具有耐高溫、耐油和耐化學腐蝕性能,確保系統的可靠運行。

治療器械:矽膠套管常用於各種治療器械和醫療設備中,如人工心臟、人工呼吸器、導尿管等。它們具有耐藥性、生物相容性和耐高溫性能,確保治療器械的安全和有效性。

高純度液體處理:矽膠套管廣泛應用於高純度液體處理和實驗室應用中。由於矽膠材料具有良好的化學穩定性和低滲透性,能夠確保液體的純度和不受污染。

矽膠套管的特性和規格可以根據具體應用的需求進行定制。製造商可以提供不同內徑

Silicone Tubing Silicone Tubing is a tubular product made of silicone material, which has the characteristics of elasticity, durability and high temperature resistance. Silicone sleeves are widely used in various industries and applications. Here's more information about silicone sleeves:

Features:

High temperature resistance: Silicone sleeves have excellent high temperature resistance, usually withstanding temperatures up to 200°C, and can be used in high temperature environments for a long time without deterioration or deformation.

Elasticity and flexibility: Silicone sleeves have good elasticity and flexibility, can twist, compress and stretch, and quickly return to their original shape after the stress is relieved, and are not easy to crack or break.

Chemical resistance: Silicone sleeves have excellent chemical resistance and are resistant to many chemicals, including acids, alkalis, solvents and oils, and are not susceptible to corrosion or damage.

Insulation properties: Silicone sleeves have excellent insulation properties and can effectively isolate current. They are used in electronic and electrical equipment to provide insulation and protection effects.

application:

Food and Beverage Industry: Silicone sleeves are commonly used in food and beverage processing and handling, such as conveying beverages, liquids or gases, and as pipes for water dispensers, coffee machines and beverage dispensing systems.

Medical and Life Sciences: Silicone sleeves are widely used in medical devices, medical equipment and life science research, such as catheters, infusion systems, bioreactors, etc., providing drug resistance, biocompatibility and high temperature tolerance.

Industry and Automation: Silicone sleeves are used in industrial fields for various fluid transfers, gas transfers, vacuum applications, etc., as well as for pipes and connections in automation systems.

Electronics and Electrical: Silicone sleeves are used for insulation and protection applications in electronic and electrical equipment, such as covering of wires and cables, insulating tubes and protective sleeves for electronic components.

The specifications of silicone sleeves can be customized according to specific application requirements, including parameters such as inner diameter, outer diameter, thickness and length. Common inner diameters range from tiny sizes to tens of millimeters, and the outer diameter and thickness are also designed as needed. Manufacturers can provide silicone sleeves that meet application requirements based on customer needs.

Silicone sleeves offer a variety of features and advantages in different applications. Here is further information:

Drinking equipment and coffee machines: Silicone sleeves are often used in water pipes in water dispensers, coffee machines and other equipment. Because silicone materials are resistant to high temperatures and chemicals, they can ensure the safety and durability of drinking water equipment.

Vacuum applications: Due to its good elasticity and sealing properties, silicone sleeves are often used in vacuum applications, such as vacuum conveying pipelines, vacuum packaging, and vacuum suction cups. They can effectively maintain vacuum pressure and achieve good sealing effect.

High-precision liquid delivery: Silicone sleeves usually have smooth inner walls to ensure high-precision liquid delivery. They are widely used in fields such as pharmaceutical dispensing, chemical experiments, and liquid analysis.

Automotive and Vehicles: Silicone sleeves are used in applications such as cooling systems, air conditioning systems and fuel systems in automobiles and other vehicles. They are resistant to high temperatures, oils and chemicals, ensuring reliable system operation.

Treatment devices: Silicone sleeves are commonly used in various treatment devices and medical equipment, such as artificial hearts, artificial respirators, urinary catheters, etc. They are drug-resistant, biocompatible and high-temperature resistant, ensuring the safety and effectiveness of therapeutic devices.

High Purity Liquid Handling: Silicone sleeves are widely used in high purity liquid handling and laboratory applications. Because silicone materials have good chemical stability and low permeability, they can ensure the purity of liquids and avoid contamination.

The characteristics and specifications of silicone sleeves can be customized to meet the needs of specific applications. Manufacturers can offer different inner diameters