矽膠軟管

矽膠軟管

矽膠軟管

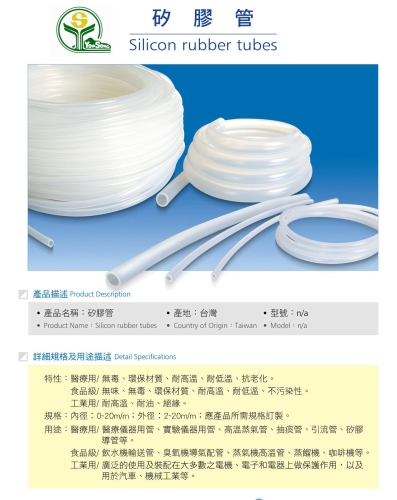

矽膠軟管是由矽膠材料製成的柔軟管道,用於傳遞各種液體、氣體或粉末。它們具有矽膠的優良特性,例如耐高溫、耐化學腐蝕、彈性和柔軟性。

矽膠軟管常見的特點包括:

耐高溫性能:矽膠軟管能夠承受高溫環境,通常耐溫範圍在-60°C至200°C之間。這使得它們非常適合於高溫流體或氣體的傳輸應用。

耐化學腐蝕性:矽膠軟管具有優異的耐化學腐蝕性,能夠抵抗許多腐蝕性化學物質,包括酸、鹼、有機溶劑等。這使得它們在化學工業和實驗室應用中非常有用。

彈性和柔軟性:矽膠軟管具有良好的彈性和柔軟性,能夠彎曲和彎折而不損壞。這使得它們容易安裝和連接,並且能夠適應複雜的管道布局。

絕緣性能:矽膠軟管具有優良的絕緣性能,可以阻止電流流失。這使得它們在電子設備、電力系統和其他需要絕緣保護的應用中非常有價值。

高透明度:某些矽膠軟管具有高透明度,使得流體或氣體的流動狀態可見,方便監測和檢查。

食品級認證:一些矽膠軟管符合食品級認證標準,可以安全地用於食品和飲料相關的應用,如飲料傳輸、食品加工和餐飲業。

矽膠軟管廣泛應用於許多行業,包括食品和飲料、醫療保健、化工、汽車、航空航天、電子等。它們常用於液體或氣體的傳輸、真空應用、冷卻系統、化學品輸送、液壓系統等。根據具體的應用需求,可以選擇適當尺寸、壁厚和特殊要求的矽膠軟管。

當選擇矽膠軟管時,以下是一些進一步的考慮因素:

尺寸和內徑:根據應用需求,確定所需的矽膠軟管尺寸和內徑。考慮流體或氣體的流量和壓力,以確保選擇適當的尺寸。

壁厚:矽膠軟管的壁厚會影響其耐壓性能和耐用性。根據應用需求和環境條件,選擇適當的壁厚。

耐壓能力:考慮矽膠軟管的耐壓能力,以確保其能夠承受應用中的壓力和負載。

彈性回復性:矽膠軟管的彈性回復性能影響其使用壽命和耐久性。較好的彈性回復性能可以減少軟管的變形和疲勞。

耐磨損性:考慮矽膠軟管的耐磨損性能,特別是當它們需要經常彎曲或接觸粗糙表面時。耐磨損性能好的軟管可以提高其使用壽命。

耐化學腐蝕性:根據應用環境中可能存在的化學藥品或溶劑,確保矽膠軟管具有足夠的耐化學腐蝕性能。

安全認證:確保所選擇的矽膠軟管符合相關的安全和品質認證標準,如FDA認證(適用於食品接觸應用)或RoHS認證(適用於無害物質)等。

廠商和供應商:選擇可靠的矽膠軟管製造商或供應商,以確保產品的質量和技術支援。研究評估不同廠商的信譽和客戶評價,選擇有良好口碑和信譽的供應商。

最後,適當的安裝和使用也是確保矽膠軟管性能的重要因素。根據製造商的指南和建議,遵循正確的安裝程序和注意事項,確保軟管獲得最佳的性能和壽命。

特點:

耐高溫:矽膠軟管能夠耐受高溫,通常可以在極端高溫環境下工作,這使得它們適用於熱處理、高溫化學反應和其他高溫應用。

耐化學腐蝕:矽膠軟管對許多化學物質具有優異的抗腐蝕性,這使得它們在涉及腐蝕性液體或氣體的應用中非常有價值。

彈性和柔軟性:矽膠軟管具有良好的彈性和柔軟性,能夠適應不同形狀和尺寸的管道,並且易於安裝和使用。

食品安全:特別設計用於食品和飲料接觸的矽膠軟管通常符合食品安全標準,可用於食品處理和包裝。

電子絕緣性:矽膠軟管通常具有良好的電子絕緣性能,因此在電子和電氣應用中常用於電線和電纜的絕緣。

應用:

食品和飲料業:矽膠軟管在食品加工、飲料生產和食品運輸過程中用於輸送液體和食品原料。

醫療行業:在醫療器械和醫療設備中,矽膠軟管用於液體輸送、藥品輸送和醫療儀器連接。

化學工業:矽膠軟管用於化學反應、試劑輸送和化學物質處理。

半導體製造:在半導體製造過程中,矽膠軟管用於處理高純度化學品和超純水。

汽車工業:在汽車製造中,矽膠軟管用於冷卻系統、供油系統和排氣系統。

包裝和印刷:矽膠軟管用於包裝機械、印刷機械和標籤應用中的液體傳遞。

航空航天:在航空航天應用中,矽膠軟管用於燃料系統、液壓系統和氣壓系統。

石油和天然氣工業:矽膠軟管在石油和天然氣行業中用於處理石油產品、化學品和氣體。

矽膠軟管由於其多功能性、耐高溫性和耐化學性,適用於多個行業和應用,有助於提供可靠的液體、氣體和粉末傳輸解決方案。無論是在食品、醫療、化學、工業、汽車、航空航天還是其他領域,矽膠軟管都發揮著重要的作用。

沖壓和模具:矽膠軟管通常用於沖壓和模具應用,因其具有優秀的彈性和柔軟性,能夠用於製造密封件、墊片和其他工業零件。

飛機維修:在航空維修中,矽膠軟管用於飛機的燃油系統、液壓系統和氣壓系統,以確保飛機的正常運作。

防震和緩衝:矽膠軟管常被用於防震和緩衝應用,例如在工業設備中,以減輕振動和震動對設備的損害。

化工處理:在化工工業中,矽膠軟管用於處理化學品、藥劑和腐蝕性液體,並且能夠在極端的化學環境下長期使用。

污水處理:矽膠軟管可用於污水處理設施,用於輸送污水和處理廢水。

能源產業:在能源產業中,矽膠軟管用於冷卻系統、熱能產生設備和液體傳輸。

環保科技:在環保科技領域,矽膠軟管用於排放控制、煙氣處理和廢棄物管理。

人造器官:由於其生物相容性,矽膠軟管可用於人造器官和醫療植入物的製造,例如心臟起搏器和人工關節。

塑料加工:在塑料加工工業中,矽膠軟管用於注塑機和挤出機等設備,以輸送塑料材料。

矽膠軟管的多功能性和耐用性使其成為各種不同行業的重要部分。無論是在工業、醫療、航空航天、環保還是其他領域,矽膠軟管都有著廣泛的應用,並在各種傳輸和處理需求中提供可靠的解決方案。

化學實驗室:矽膠軟管在化學實驗室中用於連接實驗室設備、儀器和反應容器,並用於傳輸化學試劑。

水族館和水族產業:在水族館和水族行業中,矽膠軟管可用於水泵、過濾系統和氣體傳遞,以保持水質和水族生物的健康。

高純度應用:在需要高純度、無污染和無殘留物的應用中,矽膠軟管是理想的選擇,例如在半導體製造和生物醫學領域。

高壓和真空系統:矽膠軟管能夠應對高壓和真空系統中的需求,用於高壓氣體、真空工藝和實驗室設備。

空氣壓縮:在工業和車輛維修中,矽膠軟管用於空氣壓縮系統,供應壓縮空氣給工具和設備。

水力和液壓應用:在液壓機械和設備中,矽膠軟管用於液壓油的傳遞和控制。

建築設計:矽膠軟管可用於建築設計和藝術裝置,以創造獨特的結構和藝術品。

實驗教育:在學術實驗和教育實驗中,矽膠軟管用於演示和實驗。

矽膠軟管的廣泛應用範圍使其成為許多不同領域的關鍵組件,它們提供了高度耐用、可靠的傳輸和處理解決方案。無論是在工業、科學、醫療、水處理、建築還是其他領域,矽膠軟管都有著重要的作用,並且通常符合行業標準和安全要求。

Silicone hose

Silicone hose is a flexible pipe made of silicone material, used to transfer various liquids, gases or powders. They have the excellent properties of silicone, such as high temperature resistance, chemical resistance, elasticity and softness.

Common features of silicone hose include:

High temperature resistance: Silicone hoses can withstand high temperature environments, usually between -60°C and 200°C. This makes them ideal for high temperature fluid or gas transfer applications.

Chemical resistance: Silicone hose has excellent chemical resistance and can resist many corrosive chemicals, including acids, alkalis, organic solvents, etc. This makes them very useful in chemical industry and laboratory applications.

Elasticity and softness: Silicone hose has good elasticity and softness and can be bent and bent without damage. This makes them easy to install and connect, and capable of adapting to complex piping layouts.

Insulating properties: Silicone hose has excellent insulating properties and can prevent the loss of current. This makes them valuable in electronic equipment, power systems, and other applications that require insulation protection.

High transparency: Some silicone hoses have high transparency, making the flow status of fluid or gas visible for easy monitoring and inspection.

Food Grade Certification: Some silicone hoses meet food grade certification standards and can be safely used in food and beverage related applications such as beverage transfer, food processing and catering industries.

Silicone hose is widely used in many industries, including food and beverage, healthcare, chemicals, automotive, aerospace, electronics, and more. They are commonly used in the transfer of liquids or gases, vacuum applications, cooling systems, chemical transfers, hydraulic systems, etc. Depending on the specific application needs, the appropriate size, wall thickness and special requirements of silicone hose can be selected.

When choosing silicone hose, here are some further considerations:

Size and ID: Based on application needs, determine the required silicone hose size and ID. Consider the flow rate and pressure of the fluid or gas to ensure proper sizing.

Wall Thickness: The wall thickness of a silicone hose affects its pressure resistance and durability. Select the appropriate wall thickness based on application needs and environmental conditions.

Pressure Resistance: Consider the pressure resistance of your silicone hose to ensure it can withstand the pressure and load of the application.

Elastic recovery: The elastic recovery performance of silicone hose affects its service life and durability. Better elastic recovery properties can reduce hose deformation and fatigue.

Abrasion Resistance: Consider the abrasion resistance of silicone hoses, especially if they need to be bent frequently or come into contact with rough surfaces. A hose with good wear resistance can extend its service life.

Chemical resistance: Ensure that the silicone hose has adequate chemical resistance based on chemicals or solvents that may be present in the application environment.

Safety certification: Ensure that the selected silicone hose meets relevant safety and quality certification standards, such as FDA certification (for food contact applications) or RoHS certification (for harmless substances), etc.

Manufacturers and Suppliers: Choose a reliable silicone hose manufacturer or supplier to ensure product quality and technical support. Research and evaluate the credibility and customer reviews of different vendors, and choose suppliers with good reputation and reputation.

Finally, proper installation and use are also important factors in ensuring the performance of silicone hose. Follow proper installation procedures and precautions according to manufacturer's guidelines and recommendations to ensure optimal performance and longevity of your hose.

Features:

High Temperature Resistance: Silicone hoses are able to withstand high temperatures and can often operate in extreme heat environments, making them suitable for heat treatments, high-temperature chemical reactions, and other high-temperature applications.

Chemical Resistance: Silicone hoses have excellent resistance to many chemicals, making them valuable in applications involving corrosive liquids or gases.

Elasticity and softness: Silicone hose has good elasticity and softness, can adapt to pipes of different shapes and sizes, and is easy to install and use.

Food Safety: Silicone hoses specifically designed for food and beverage contact generally meet food safety standards and can be used in food handling and packaging.

Electronic Insulation: Silicone hose generally has good electronic insulation properties and is therefore commonly used to insulate wires and cables in electronic and electrical applications.

application:

Food and Beverage Industry: Silicone hoses are used to transport liquids and food ingredients during food processing, beverage production and food transportation.

Medical industry: In medical devices and equipment, silicone hoses are used for liquid delivery, drug delivery, and medical instrument connections.

Chemical industry: Silicone hoses are used in chemical reactions, reagent transportation and chemical substance handling.

Semiconductor Manufacturing: In the semiconductor manufacturing process, silicone hose is used to handle high-purity chemicals and ultrapure water.

Automobile industry: In automobile manufacturing, silicone hoses are used in cooling systems, fuel supply systems, and exhaust systems.

Packaging and Printing: Silicone hose is used for liquid transfer in packaging machinery, printing machinery and labeling applications.

Aerospace: In aerospace applications, silicone hose is used in fuel systems, hydraulic systems, and pneumatic systems.

Oil and Gas Industry: Silicone hoses are used in the oil and gas industry to handle petroleum products, chemicals and gases.

Silicone hose is suitable for multiple industries and applications due to its versatility, high temperature resistance and chemical resistance, helping to provide reliable liquid, gas and powder transfer solutions. Whether in food, medical, chemical, industrial, automotive, aerospace or other fields, silicone hoses play an important role.

Stamping and molding: Silicone hose is commonly used in stamping and molding applications because of its excellent elasticity and flexibility, which can be used to make seals, gaskets and other industrial parts.

Aircraft maintenance: In aviation maintenance, silicone hoses are used in the fuel system, hydraulic system and pneumatic system of the aircraft to ensure the normal operation of the aircraft.

Shockproof and cushioning: Silicone hose is often used in shockproof and cushioning applications, such as in industrial equipment, to reduce damage to equipment from vibration and shock.

Chemical Processing: In the chemical industry, silicone hoses are used to handle chemicals, agents, and corrosive liquids and can withstand long-term use in extreme chemical environments.

Sewage treatment: Silicone hoses can be used in sewage treatment facilities to transport sewage and treat wastewater.

Energy Industry: In the energy industry, silicone hose is used in cooling systems, heat generation equipment and liquid transfer.

Environmental Technology: In the field of environmental technology, silicone hoses are used in emission control, flue gas treatment and waste management.

Artificial Organs: Due to its biocompatibility, silicone hoses are used in the manufacture of artificial organs and medical implants, such as pacemakers and artificial joints.

Plastic Processing: In the plastic processing industry, silicone hose is used in equipment such as injection molding machines and extruders to transport plastic materials.

The versatility and durability of silicone hose make it an important part of a variety of different industries. Whether in industry, medical, aerospace, environmental protection or other fields, silicone hoses have a wide range of applications and provide reliable solutions in a variety of transfer and handling needs.

Chemistry laboratory: Silicone hoses are used in chemical laboratories to connect laboratory equipment, instruments and reaction vessels, and to transport chemical reagents.

Aquarium and Aquarium Industry: In the aquarium and aquarium industry, silicone hose is used in water pumps, filtration systems and gas transfer to maintain water quality and the health of aquatic life.

High Purity Applications: Silicone hose is ideal in applications that require high purity, no contamination and no residue, such as in semiconductor manufacturing and biomedical fields.

High Pressure and Vacuum Systems: Silicone hoses are designed to handle the needs of high pressure and vacuum systems for use with high pressure gases, vacuum processes and laboratory equipment.

Air Compression: In industry and vehicle maintenance, silicone hose is used in air compression systems to supply compressed air to tools and equipment.

Hydraulic and Hydraulic Applications: In hydraulic machinery and equipment, silicone hoses are used for the transfer and control of hydraulic oil.

Architectural Design: Silicone hose can be used in architectural design and art installations to create unique structures and works of art.

Experimental Education: In academic experiments and educational experiments, silicone hose is used for demonstrations and experiments.

The wide range of applications for silicone hoses makes them a key component in many different sectors, providing highly durable, reliable transfer and handling solutions. Whether in industry, science, medical, water treatment, construction or other fields, silicone hoses serve an important purpose and often comply with industry standards and safety requirements.