電動車矽膠零組件

電動車矽膠零組件 電動車矽膠零組件

電動車矽膠零組件 電動車矽膠零組件

電動車中使用的矽膠零組件通常用於提供密封、絕緣和防水功能。以下是一些可能的矽膠零組件在電動車中的應用:

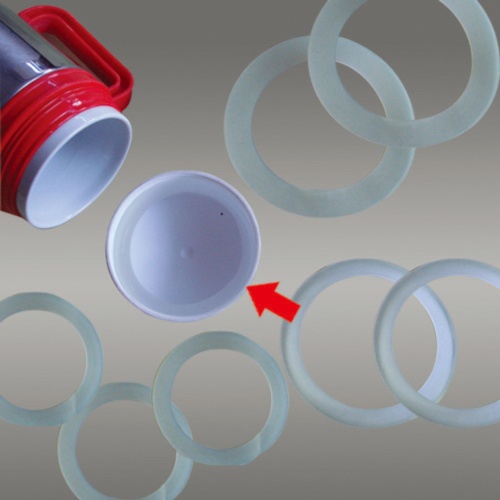

密封圈:矽膠密封圈用於電動車的各種部件,如電池包、電機、控制器等的接合處。這些密封圈能夠防止水分、灰塵和其他雜質進入關鍵零件,確保其正常運作。

線束保護套:電動車中的電纜和線束需要良好的保護,以避免受到振動、擦傷和外部環境的損壞。矽膠保護套可用於對電纜和線束進行包裹和絕緣,提供額外的耐用性和彈性。

接線端子密封:電動車中的電纜和接線端子需要防水和密封處理,以防止潮濕和其他環境因素對電路造成損壞。矽膠可以應用於接線端子的密封處理,確保其電氣性能和安全性。

電池絕緣墊片:電動車的電池系統需要良好的絕緣性能,以防止電池單體之間的短路和電池系統的故障。矽膠絕緣墊片可以應用於電池模塊的間隔和絕緣,提供安全的電池包結構。

其他應用:矽膠還可以用於電動車的其他零組件,如電動機的防水罩、充電插頭密封等。它們能夠提供良好的耐用性、耐高溫性和化學穩定性。

總的來說,矽膠零組件在電動車中扮演著重要的角色,確保關鍵部件的密封、絕緣和防水性能,同時提供了安全、可靠的運行環境。

當然!以下是一些可能的矽膠零組件在電動車中的進一步應用:

車窗密封:矽膠可用於車窗和風擋玻璃的密封,確保良好的密閉性和防水性能。這有助於隔絕外部噪音和環境條件,提供更安靜、舒適的車內環境。

燈具密封:矽膠被廣泛應用於車輛照明系統中的燈具密封,例如前燈、尾燈、轉向燈等。這些矽膠密封件能夠防止水分滲入燈具內部,確保照明系統的正常運作。

電動車充電插座密封:矽膠被用於電動車充電插座的密封,確保充電接口的防水和耐久性。這對於外部環境的潮濕和污垢是至關重要的,同時保護充電系統免受損壞。

輪胎氣密性:矽膠被用於輪胎的氣密性密封,確保輪胎能夠保持適當的氣壓。這對於提高行車安全性、節省能源和延長輪胎壽命都非常重要。

電池散熱管理:在電動車中,矽膠材料可以用於電池散熱管理,例如作為散熱片或散熱膠,以提高電池系統的散熱效率,防止過熱並延長電池壽命。

這只是一些例子,矽膠零組件在電動車中的應用非常廣泛,其靈活性、耐用性和耐候性使其成為許多關鍵部件的理想選擇。隨著電動車市場的不斷發展,矽膠零組件的應用也將不斷擴展和創新。

Silicone components for electric vehicles Silicone components for electric vehicles

Silicone components used in electric vehicles are often used to provide sealing, insulation and waterproofing. Here are some possible applications of silicone components in electric vehicles:

Sealing rings: Silicone sealing rings are used at the joints of various components of electric vehicles, such as battery packs, motors, controllers, etc. These seals prevent moisture, dust and other impurities from entering critical parts, ensuring they function properly.

Wire Harness Protective Covers: Cables and wire harnesses in electric vehicles require good protection from vibration, abrasions, and damage from the external environment. Silicone sleeves can be used to wrap and insulate cables and wire harnesses, providing extra durability and resiliency.

Terminal sealing: Cables and terminal blocks in electric vehicles require waterproofing and sealing to prevent moisture and other environmental factors from causing damage to the circuits. Silicone can be used to seal terminal blocks to ensure their electrical performance and safety.

Battery insulation gasket: The battery system of electric vehicles requires good insulation performance to prevent short circuits between battery cells and failure of the battery system. Silicone insulating gaskets can be used to space and insulate battery modules to provide a safe battery pack structure.

Other applications: Silicone can also be used in other components of electric vehicles, such as waterproof covers for electric motors, sealing of charging plugs, etc. They offer good durability, high temperature resistance and chemical stability.

In general, silicone components play an important role in electric vehicles, ensuring the sealing, insulation and waterproof performance of key components, while providing a safe and reliable operating environment.

certainly! Here are some possible further applications of silicone components in electric vehicles:

Car window sealing: Silicone can be used to seal car windows and windshields to ensure good sealing and waterproof performance. This helps isolate outside noise and environmental conditions, providing a quieter, more comfortable interior.

Lamp sealing: Silicone is widely used in lamp sealing in vehicle lighting systems, such as headlights, taillights, turn signals, etc. These silicone seals prevent moisture from penetrating into the fixture, ensuring the proper functioning of the lighting system.

Electric vehicle charging socket sealing: Silicone is used to seal electric vehicle charging sockets to ensure the waterproofing and durability of the charging interface. This is vital against moisture and dirt from the external environment, while protecting the charging system from damage.

Tire Air Tightness: Silicone is used to airtightly seal tires to ensure that the tires can maintain proper air pressure. This is very important for improving driving safety, saving energy and extending tire life.

Battery heat dissipation management: In electric vehicles, silicone materials can be used for battery heat dissipation management, such as as heat sinks or heat dissipation glue, to improve the heat dissipation efficiency of the battery system, prevent overheating and extend battery life.

These are just a few examples, silicone components are widely used in electric vehicles, and their flexibility, durability and weather resistance make them ideal for many critical components. As the electric vehicle market continues to develop, the application of silicone components will continue to expand and innovate.