矽膠墊片

矽膠墊片

矽膠墊片

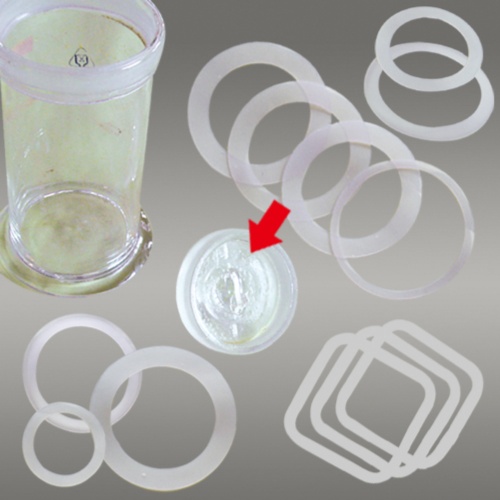

矽膠墊片是由矽膠材料製成的薄片狀產品,通常用於填充、緩衝、隔離或密封應用。它們具有矽膠的特性,如彈性、耐高溫、耐化學腐蝕和耐久性。

矽膠墊片的特點如下:

彈性和柔軟性:矽膠墊片具有優異的彈性和柔軟性,可以適應不同表面的形狀和大小,提供緩衝和密封效果。

耐高溫性能:矽膠墊片能夠承受高溫環境,通常耐溫範圍在-60°C至200°C之間。這使得它們適用於需要耐高溫性能的應用。

耐化學腐蝕性:矽膠墊片具有良好的耐化學腐蝕性能,能夠抵抗許多腐蝕性物質,如酸、鹼、油和溶劑。這使得它們在化學工業和實驗室應用中非常有用。

良好的密封性能:矽膠墊片具有良好的密封性能,可以填補表面間的間隙,防止液體、氣體或塵埃的滲入。

抗老化性能:矽膠墊片具有優異的抗老化性能,能夠抵抗紫外線、氧氣和大氣污染物的侵蝕,延長使用壽命。

食品級認證:某些矽膠墊片符合食品級認證要求,可以安全地應用於食品和醫療相關的應用。

矽膠墊片廣泛應用於各個行業,如機械、電子、汽車、航空航天、醫療等。常見的應用包括密封墊圈、隔振墊片、緩衝墊片、絕緣墊片、防震墊片等。根據具體的應用需求,矽膠墊片可以有不同的尺寸、形狀、厚度和硬度。選擇適當的矽膠墊片應根據應用的環境條件、材料要求和功能要求進行評估。

當選擇矽膠墊片時,以下是一些進一步的考慮因素:

厚度和尺寸:確定所需的矽膠墊片的厚度和尺寸,以符合應用中的間隙或表面要求。根據需要的壓縮程度或填補的空間,選擇適當的墊片厚度。

硬度:矽膠墊片的硬度可以影響其壓縮性、彈性和密封性能。根據應用需求,選擇適合的硬度範圍。

耐壓能力:考慮矽膠墊片的耐壓能力,特別是在需要承受壓力或負載的應用中。確保選擇的墊片能夠應對預期的壓力要求。

耐化學腐蝕性:根據應用環境中可能存在的化學物質,選擇具有耐化學腐蝕性的矽膠墊片。確保墊片能夠耐受可能的腐蝕性物質。 矽膠墊片

矽膠墊片

高溫性能:根據應用中的溫度要求,確保選擇的矽膠墊片能夠耐受高溫環境。考慮所需的耐高溫範圍和溫度穩定性。

色彩選擇:矽膠墊片通常有不同的顏色可供選擇,如透明、白色、黑色等。根據應用需求,選擇適合的顏色。

安全認證:確保所選擇的矽膠墊片符合相關的安全和品質認證標準,如FDA認證(適用於食品接觸應用)或RoHS認證(適用於無害物質)等。

廠商和供應商:選擇可靠的矽膠墊片製造商或供應商,以確保產品質量和技術支援。研究評估不同廠商的信譽和客戶評價,選擇有良好口碑和信譽的供應商。

請注意,選擇適當的矽膠墊片時,需要根據具體的應用需求和環境條件進行評估,並與製造商或供應商進一步溝通,以確保選擇最適合的產品。

矽膠墊片是一種由矽膠材料製成的薄片狀產品,通常用於填充、緩衝、隔離或密封應用。它們具有矽膠的特性,如彈性、耐高溫、耐化學腐蝕和耐久性。以下是矽膠墊片的一些特點和應用:

特點:

彈性和柔軟性:矽膠墊片具有優異的彈性和柔軟性,能夠在壓力下變形並恢復原狀。

耐高溫性:它們能夠耐受高溫,通常在-50°C至200°C之間工作,這使得它們適用於高溫環境中的密封和緩衝應用。

耐化學腐蝕性:矽膠墊片對許多化學品、溶劑和油類都具有優異的耐腐蝕性,這使得它們在化學工業中有用。

電絕緣性:某些矽膠墊片具有良好的電絕緣性能,因此可用於電子和電氣應用中。

食品安全:特別設計用於食品接觸的矽膠墊片通常符合食品安全標準,可用於食品包裝和處理。

耐候性:它們具有出色的耐候性,能夠長時間抵抗紫外線、氧氣和潮濕環境的影響。

高精度:矽膠墊片通常具有高度精確的尺寸和表面光滑度,適用於需要高精度的應用。

應用:

機械密封:矽膠墊片常用於機械密封,如閥門、管道和泵的密封。

電子絕緣:它們用於電子設備中的電絕緣、緩衝和絕緣材料。

醫療器械:矽膠墊片用於醫療器械和醫療設備中,如血壓計、心臟瓣膜和醫療密封件。

飛機航空:在航空航天領域,它們用於飛機的絕緣、密封和緩衝。

食品包裝:用於食品包裝的矽膠墊片可用於瓶蓋密封、食品容器和食品橡膠墊。

汽車工業:在汽車工業中,矽膠墊片用於引擎部件、排氣系統和冷卻系統的密封和緩衝。

建築絕緣:用於建築絕緣,如門窗密封條和絕緣墊片。

總之,矽膠墊片是一種多功能且高性能的材料,適用於各種不同的行業和應用領域。它們提供了可靠的密封、緩衝、隔離和填充解決方案,並且通常符合特定行業的要求和標準。

當談到矽膠墊片時,還有一些其他方面和應用值得了解:

食品處理和包裝:特別設計用於食品處理和包裝的矽膠墊片常用於食品容器的密封、食品包裝的真空密封和食品處理設備的緩衝。

高真空應用:矽膠墊片在高真空環境中表現出色,因此在實驗室、科學研究和太空應用中使用廣泛。

半導體製造:由於其高純度和耐高溫性能,矽膠墊片在半導體製造和微納米技術中用於製造緩衝墊、絕緣層和封裝。

防水和防潮:矽膠墊片通常用於防水和防潮應用,如水龍頭、浴缸和淋浴門的密封。

藝術和工藝:藝術家和工藝品製作者使用矽膠墊片來製作模型、雕塑和藝術品,因為它們可以輕易地創建複雜的形狀和紋理。

設備維護:矽膠墊片可用於設備維護,如汽車引擎的密封、管道的維護和機械設備的緩衝。

氣密性測試:在氣密性測試中,矽膠墊片用於密封測試設備或容器,以確保不會發生氣體或液體泄漏。

音頻和音響:矽膠墊片用於音頻和音響設備的緩衝和隔音,以提供更好的聲音質量。

總的來說,矽膠墊片是一種多功能的材料,廣泛應用於多個領域,提供了填充、緩衝、密封和隔離等功能。它們通常具有卓越的性能,如彈性、耐高溫性、耐化學腐蝕性和生物相容性,使其成為許多應用的理想選擇。無論是在工業、醫療、科學、藝術還是其他領域,矽膠墊片都能夠提供可靠的解決方案。

Silicone gasket

Silicone gaskets are thin sheet-like products made of silicone material that are typically used in filling, cushioning, isolating or sealing applications. They share the properties of silicone, such as elasticity, resistance to high temperatures, resistance to chemicals and durability.

The characteristics of silicone gaskets are as follows:

Elasticity and softness: Silicone gaskets have excellent elasticity and softness and can adapt to the shape and size of different surfaces, providing cushioning and sealing effects.

High temperature resistance: Silicone gaskets can withstand high temperature environments, usually between -60°C and 200°C. This makes them suitable for applications requiring high temperature performance.

Chemical resistance: Silicone gaskets have good chemical resistance and can resist many corrosive substances, such as acids, alkalis, oils and solvents. This makes them very useful in chemical industry and laboratory applications.

Good sealing performance: Silicone gaskets have good sealing performance and can fill the gaps between surfaces to prevent the penetration of liquid, gas or dust.

Anti-aging performance: Silicone gaskets have excellent anti-aging properties and can resist the erosion of ultraviolet rays, oxygen and atmospheric pollutants, extending their service life.

Food Grade Certification: Certain silicone gaskets meet food grade certification requirements and can be used safely in food and medical related applications.

Silicone gaskets are widely used in various industries, such as machinery, electronics, automobiles, aerospace, medical, etc. Common applications include sealing gaskets, vibration isolation gaskets, buffer gaskets, insulating gaskets, anti-vibration gaskets, etc. Silicone gaskets are available in different sizes, shapes, thicknesses and hardnesses depending on the specific application needs. Selection of the appropriate silicone gasket should be evaluated based on the environmental conditions, material requirements, and functional requirements of the application.

When selecting silicone gaskets, here are some further considerations:

Thickness and Size: Determine the thickness and size of silicone gasket required to match the gap or surface requirements in your application. Choose the appropriate gasket thickness based on the amount of compression required or space to fill.

Hardness: The hardness of a silicone gasket can affect its compressibility, elasticity and sealing performance. Select the appropriate hardness range based on application requirements.

Pressure Resistance: Consider the pressure resistance of a silicone gasket, especially in applications that require it to withstand pressure or load. Make sure the gasket you choose can handle the expected pressure requirements.

Chemical resistance: Choose a silicone gasket that is chemically resistant based on the chemicals that may be present in the application environment. Make sure the gasket can withstand potentially corrosive substances. Silicone gasket

High temperature performance: Based on the temperature requirements of the application, ensure that the silicone gasket selected can withstand high temperature environments. Consider the required high temperature range and temperature stability.

Color selection: Silicone gaskets are usually available in different colors, such as transparent, white, black, etc. Choose the appropriate color based on application needs.

Safety certification: Ensure that the selected silicone gasket meets relevant safety and quality certification standards, such as FDA certification (for food contact applications) or RoHS certification (for harmless substances), etc.

Manufacturers and Suppliers: Choose a reliable silicone gasket manufacturer or supplier to ensure product quality and technical support. Research and evaluate the credibility and customer reviews of different vendors, and choose suppliers with good reputation and reputation.

Please note that selecting the appropriate silicone gasket requires evaluation based on specific application needs and environmental conditions, and further communication with the manufacturer or supplier to ensure the most suitable product is selected.

A silicone gasket is a thin sheet-like product made of silicone material that is typically used in filling, cushioning, isolating or sealing applications. They share the properties of silicone, such as elasticity, resistance to high temperatures, resistance to chemicals and durability. Here are some features and applications of silicone gaskets:

Features:

Elasticity and Softness: Silicone gaskets have excellent elasticity and softness, able to deform and return to their original shape under pressure.

High Temperature Resistance: They are able to withstand high temperatures, typically operating between -50°C and 200°C, making them suitable for sealing and buffering applications in high temperature environments.

Chemical Resistance: Silicone gaskets have excellent resistance to many chemicals, solvents, and oils, making them useful in the chemical industry.

Electrical Insulating Properties: Some silicone gaskets have good electrical insulating properties and are therefore used in electronic and electrical applications.

Food Safety: Silicone gaskets specifically designed for food contact generally meet food safety standards and can be used in food packaging and handling.

Weather Resistance: They have excellent weather resistance and can withstand the effects of UV rays, oxygen and humid environments for a long time.

High Precision: Silicone gaskets typically have highly precise dimensions and surface smoothness, making them suitable for applications requiring high precision.

application:

Mechanical seals: Silicone gaskets are commonly used for mechanical seals, such as valves, pipes and pumps.

Electronic Insulation: They are used in electrical insulation, buffering and insulating materials in electronic equipment.

Medical Devices: Silicone gaskets are used in medical devices and equipment such as blood pressure monitors, heart valves and medical seals.

Aircraft Aviation: In the aerospace sector, they are used for insulation, sealing and cushioning in aircraft.

Food packaging: Silicone gaskets for food packaging can be used for bottle cap seals, food containers and food rubber gaskets.

Automotive Industry: In the automotive industry, silicone gaskets are used to seal and cushion engine components, exhaust systems, and cooling systems.

Building insulation: used for building insulation, such as door and window sealing strips and insulating gaskets.

In summary, silicone gaskets are a versatile and high-performance material suitable for use in a variety of different industries and applications. They provide reliable sealing, cushioning, isolating and filling solutions and often comply with industry-specific requirements and standards.

When it comes to silicone gaskets, there are a few other aspects and applications worth knowing about:

Food Handling and Packaging: Silicone gaskets specifically designed for use in food handling and packaging are commonly used to seal food containers, vacuum seal food packaging and cushion food handling equipment.

High Vacuum Applications: Silicone gaskets perform well in high vacuum environments, making them widely used in laboratories, scientific research, and space applications.

Semiconductor Manufacturing: Due to its high purity and high temperature resistance, silicone gaskets are used in semiconductor manufacturing and micro-nano technology to create cushioning pads, insulating layers and packaging.

Waterproofing and Moistureproofing: Silicone gaskets are commonly used in waterproofing and moistureproofing applications such as sealing faucets, tubs, and shower doors.

Arts and Crafts: Artists and craft makers use silicone spacers to create models, sculptures, and artwork because they can easily create complex shapes and textures.

Equipment maintenance: Silicone gaskets can be used for equipment maintenance, such as sealing of automobile engines, maintenance of pipelines and buffering of mechanical equipment.

Air Tightness Testing: In air tightness testing, silicone gaskets are used to seal test equipment or containers to ensure that no gas or liquid leakage occurs.

Audio and Sound: Silicone gaskets are used for cushioning and sound isolation in audio and sound equipment to provide better sound quality.

In general, silicone gaskets are a versatile material that are widely used in many fields to provide filling, buffering, sealing and isolation functions. They often have excellent properties such as elasticity, high temperature resistance, chemical resistance and biocompatibility, making them ideal for many applications. Whether in industry, medical, science, art or other fields, silicone gaskets provide reliable solutions.