電動車塑膠製品

電動車塑膠製品

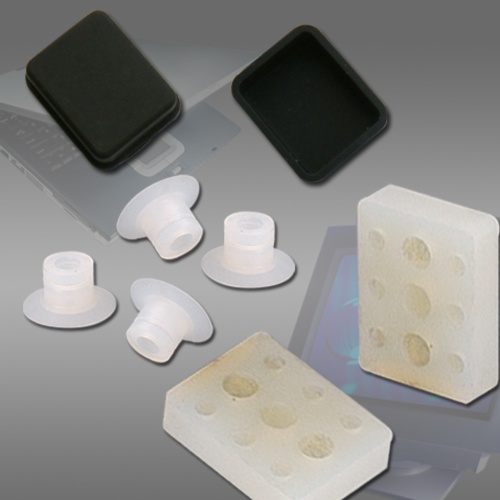

電動車塑膠製品電動車塑膠製品(Plastic Components for Electric Vehicles)是指應用於電動車輛中的各種塑膠製品和零件。隨著電動車的快速發展,塑膠製品在電動車的設計和製造中起著重要的角色。以下是關於電動車塑膠製品的一些相關信息:

電動車塑膠製品電動車塑膠製品(Plastic Components for Electric Vehicles)是指應用於電動車輛中的各種塑膠製品和零件。隨著電動車的快速發展,塑膠製品在電動車的設計和製造中起著重要的角色。以下是關於電動車塑膠製品的一些相關信息:

內飾零件:塑膠內飾零件在電動車中起到裝飾和功能性的作用。例如,儀表板、中控台、門板、座椅和車內裝飾等都可以使用塑膠製成,提供舒適的車內環境和功能性設計。

外觀零件:電動車的外觀零件通常也使用塑膠材料。這包括車身外殼、車門、車頭燈、尾燈、車窗框等。塑膠外觀零件不僅可以提供外觀設計的自由度,還能降低車輛的整體重量,提高能源效率。

電池和充電設施部件:電動車的電池系統和充電設施中也使用塑膠製品。這些塑膠零件通常用於電池包裝、連接件、隔熱材料和充電插座等,確保電池系統的安全性和功能性。

傳動系統和底盤零件:塑膠製品還可以應用於電動車的傳動系統和底盤部件。例如,塑膠制動件、懸掛件、導流板和防護罩等都可以使用塑膠材料,提供輕量化、噪音減少和耐用性。

充電線材和連接器:電動車的充電線材和連接器也使用塑膠材料,以提供絕緣和保護功能。這些塑膠零件必須具有良好的耐高溫、耐磨損和耐化學腐蝕性能,以確保充電過程的安全和效率。

塑膠製品在電動車中具有輕量化、設計自由度和功能性的優勢。製造商可以根據電動車的需求和規格進行定制,以確保塑膠製品的符合要求。同時,為確保塑膠製品的可持續性,製造商也在不斷努力尋找和開發更環保的塑膠材料和製造過程。

當然!以下是關於電動車塑膠製品的更多信息:

車燈和信號燈:電動車的照明系統中使用了多種塑膠製品,如前燈、尾燈、轉向燈和煞車燈等。這些燈具通常由透明或半透明的塑膠材料製成,提供光學效果和保護燈具內部組件。

充電插頭和插座:充電插頭和插座是電動車充電系統的關鍵部分,其中使用塑膠材料進行絕緣和連接。塑膠製品確保了安全的充電過程並提供可靠的電氣連接。

儲物空間和置物箱:塑膠製品在電動車的儲物空間和置物箱中扮演重要角色。例如,中央儲物箱、門板上的儲物格和杯架等通常由塑膠製成,提供便利的儲物空間和功能。

電動車內部零件:塑膠製品還用於電動車內部的其他零件,如空調出風口、按鈕和旋鈕、方向盤覆蓋等。它們提供舒適的操作體驗和優雅的內飾設計。

可充電電池外殼:塑膠材料常用於電動車可充電電池的外殼。這些外殼需要提供優異的絕緣性和保護性,同時具有輕量化的特點,以確保電池的安全運行。

外部車身保護件:電動車的外部車身保護件,如車門護板、輪拱和前擋泥板等,也常使用塑膠製品。它們能夠提供對車身的保護,同時減輕車輛重量,提高能源效率。

環保塑膠材料:隨著對環境保護的重視,製造商也在開發和使用環保塑膠材料,如可回收材料和生物可分解材料,以減少對環境的影響。

電動車塑膠製品的選擇和設計取決於多個因素,包括性能需求、外觀要求、耐久性和成本效益等。製造商通常與電動車生產商合作,根據特定車型的要求定制塑膠製品。

Electric vehicle plastic products

Plastic Components for Electric Vehicles Plastic Components for Electric Vehicles refers to various plastic products and parts used in electric vehicles. With the rapid development of electric vehicles, plastic products play an important role in the design and manufacturing of electric vehicles. The following is some relevant information about plastic products for electric vehicles:

Interior parts: Plastic interior parts play a decorative and functional role in electric vehicles. For example, dashboards, center consoles, door panels, seats and interior decorations can all be made of plastic to provide a comfortable interior environment and functional design.

Appearance parts: Appearance parts of electric vehicles usually also use plastic materials. This includes the body shell, doors, headlights, taillights, window frames and more. Plastic exterior parts not only provide freedom in exterior design, but also reduce the overall weight of the vehicle and improve energy efficiency.

Battery and charging facility components: Plastic products are also used in battery systems and charging facilities for electric vehicles. These plastic parts are usually used in battery packaging, connectors, insulation materials and charging sockets to ensure the safety and functionality of the battery system.

Transmission system and chassis parts: Plastic products can also be used in the transmission system and chassis components of electric vehicles. For example, plastic brake parts, suspension parts, deflectors and protective covers can all use plastic materials to provide lightweight, noise reduction and durability.

Charging cables and connectors: Electric vehicle charging cables and connectors also use plastic materials to provide insulation and protection. These plastic parts must have good resistance to high temperatures, wear and chemical corrosion to ensure the safety and efficiency of the charging process.

Plastic products have the advantages of lightweight, design freedom and functionality in electric vehicles. Manufacturers can customize according to the needs and specifications of electric vehicles to ensure that the plastic products meet the requirements. At the same time, to ensure the sustainability of plastic products, manufacturers are constantly working hard to find and develop more environmentally friendly plastic materials and manufacturing processes.

certainly! Here is more information about plastic products for electric vehicles:

Car lights and signal lights: A variety of plastic products are used in the lighting system of electric vehicles, such as headlights, taillights, turn signals and brake lights. These fixtures are typically made from clear or translucent plastic materials that provide optical effects and protect the fixture's internal components.

Charging plugs and sockets: Charging plugs and sockets are critical parts of electric vehicle charging systems, using plastic materials for insulation and connections. The plastic ensures a safe charging process and provides a reliable electrical connection.

Storage spaces and glove compartments: Plastic products play an important role in the storage spaces and glove compartments of electric vehicles. For example, the central storage box, storage compartments on the door panels and cup holders are usually made of plastic, providing convenient storage space and functionality.

Internal parts of electric vehicles: Plastic products are also used in other internal parts of electric vehicles, such as air-conditioning outlets, buttons and knobs, steering wheel covers, etc. They offer comfortable operation and elegant interior design.

Rechargeable battery casing: Plastic materials are often used in the casing of rechargeable batteries for electric vehicles. These enclosures need to provide excellent insulation and protection while being lightweight to ensure safe battery operation.

External body protection parts: Plastic products are also often used for external body protection parts of electric vehicles, such as door guards, wheel arches and front fenders. They provide body protection while reducing vehicle weight and improving energy efficiency.

Environmentally friendly plastic materials: With the emphasis on environmental protection, manufacturers are also developing and using environmentally friendly plastic materials, such as recyclable materials and biodegradable materials, to reduce the impact on the environment.

The selection and design of plastic products for electric vehicles depends on multiple factors, including performance requirements, appearance requirements, durability and cost-effectiveness. Manufacturers often work with electric vehicle manufacturers to customize plastic products according to the requirements of specific models.