耐熱墊片

耐熱墊片(矽膠)

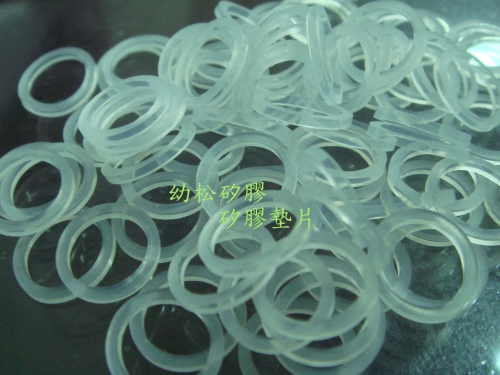

耐熱墊片(矽膠)耐熱墊片是一種使用矽膠材料製成的墊片,具有優異的耐熱性能。它通常用於需要承受高溫或高熱量的應用中,以提供隔熱、保護或密封的功能。

耐熱墊片(矽膠)耐熱墊片是一種使用矽膠材料製成的墊片,具有優異的耐熱性能。它通常用於需要承受高溫或高熱量的應用中,以提供隔熱、保護或密封的功能。

以下是耐熱墊片(矽膠)的特點和應用:

耐高溫性:矽膠材料具有優異的耐高溫性能,能夠在高溫環境下保持其物理性質和性能。耐熱墊片可以承受高溫至數百攝氏度,並保持穩定性和可靠性。

彈性和柔軟性:矽膠材料具有優秀的彈性和柔軟性,能夠適應不同形狀和表面的密封需求。耐熱墊片能夠提供有效的密封、防塵和隔熱效果。

耐化學性:矽膠材料具有良好的耐化學性,能夠抵抗多種化學物質的侵蝕,包括酸、鹼、溶劑等。這使得耐熱墊片能夠在惡劣環境中保持其性能和壽命。

電絕緣性:矽膠材料具有優異的電絕緣性能,能夠有效阻隔電流傳導。這使得耐熱墊片適用於電氣和電子應用中的絕緣、隔熱和保護。

機械強度:耐熱墊片的矽膠材料通常具有優異的機械強度和耐久性,能夠承受壓力、振動和機械應力。

耐熱墊片(矽膠)常用於許多高溫應用,包括:

高溫密封:用於密封熱交換器、爐灶、汽車引擎等高溫設備,防止氣體或液體洩漏。

隔熱和保護:用於隔熱墊、熱屏障、熱阻墊片等,以防止熱能傳導或保護附近組件不受高溫損害。

熱塑性成型:用於熱壓成型或熱膨脹成型的模具墊片,以在高溫和壓力下形成所需形狀。

電子散熱:用於散熱墊、導熱墊等,以提供熱管理和散熱功能。

在選擇和應用耐熱墊片時,應考慮所需的耐熱溫度範圍、形狀尺寸、耐化學性和機械強度等要素,確保適合特定的應用需求。

當然,以下是更多關於矽膠耐熱墊片的資訊:

耐氧化性:矽膠耐熱墊片具有優異的耐氧化性,能夠抵抗氧氣和氧化物的侵蝕。這使得它們在高溫環境中能夠長時間保持穩定性和性能。

食品級材料:某些矽膠耐熱墊片符合食品級標準,可以安全用於食品加工和處理設備中,提供耐高溫的密封和保護。

尺寸和形狀多樣化:矽膠耐熱墊片可根據具體應用需求製作成各種尺寸和形狀,包括圓形、方形、矩形和特殊形狀,以確保與目標設備的密合度。

粘合性:某些矽膠耐熱墊片具有雙面黏膠背膠,使其能夠輕鬆黏貼於需要密封或保護的表面上,簡化安裝過程。

與其他材料的兼容性:矽膠耐熱墊片與其他材料(如金屬、塑料等)具有良好的兼容性,能夠與其他組件或材料有效地結合。

矽膠耐熱墊片廣泛應用於許多行業,包括汽車、航空航天、能源、電子、食品加工等。它們在提供耐高溫密封、隔熱和保護的同時,也能提升設備的效能和可靠性。

在選擇矽膠耐熱墊片時,應根據具體應用的要求,例如所需的耐熱溫度範圍、化學耐性、耐久性和尺寸等因素進行選擇,以確保獲得最佳的性能和效果。

Heat-resistant gasket (silicone)

Heat-resistant gasket (silicone) Heat-resistant gasket is a gasket made of silicone material and has excellent heat resistance. It is often used in applications that need to withstand high temperatures or heat to provide insulation, protection or sealing.

The following are the characteristics and applications of heat-resistant gaskets (silicone):

High temperature resistance: Silicone materials have excellent high temperature resistance and can maintain their physical properties and performance in high temperature environments. Heat-resistant gaskets can withstand high temperatures to hundreds of degrees Celsius and maintain stability and reliability.

Elasticity and softness: Silicone material has excellent elasticity and softness, and can adapt to the sealing needs of different shapes and surfaces. Heat-resistant gaskets provide effective sealing, dust protection and thermal insulation.

Chemical resistance: Silicone material has good chemical resistance and can resist the erosion of various chemical substances, including acids, alkalis, solvents, etc. This allows the heat-resistant gasket to maintain its performance and longevity in harsh environments.

Electrical insulation: Silicone material has excellent electrical insulation properties and can effectively block current conduction. This makes heat-resistant gaskets suitable for insulation, insulation and protection in electrical and electronic applications.

Mechanical strength: The silicone material of heat-resistant gaskets generally has excellent mechanical strength and durability, and can withstand pressure, vibration and mechanical stress.

Heat-resistant gaskets (silicone) are commonly used in many high-temperature applications, including:

High-temperature sealing: Used to seal high-temperature equipment such as heat exchangers, stoves, and automobile engines to prevent gas or liquid leakage.

Thermal Insulation and Protection: Used in thermal pads, thermal barriers, thermal resistance pads, etc. to prevent thermal energy conduction or protect nearby components from high temperature damage.

Thermoplastic Molding: Mold gaskets used in thermoforming or thermal expansion molding to form the desired shape under high temperature and pressure.

Electronic cooling: used in cooling pads, thermal pads, etc. to provide thermal management and heat dissipation functions.

When selecting and applying heat-resistant gaskets, factors such as the required heat-resistant temperature range, shape and size, chemical resistance, and mechanical strength should be considered to ensure that they are suitable for specific application needs.

Of course, here is more information about silicone heat-resistant gaskets:

Oxidation resistance: Silicone heat-resistant gaskets have excellent oxidation resistance and can resist the erosion of oxygen and oxides. This allows them to maintain stability and performance over time in high temperature environments.

Food-grade materials: Certain silicone heat-resistant gaskets meet food-grade standards and can be safely used in food processing and handling equipment to provide high-temperature sealing and protection.

Diversified Sizes and Shapes: Silicone heat-resistant gaskets can be manufactured in a variety of sizes and shapes based on specific application needs, including round, square, rectangular and special shapes to ensure a tight fit with the target device.

Adhesion: Some silicone heat-resistant gaskets have double-sided adhesive backing, allowing them to be easily adhered to surfaces that need to be sealed or protected, simplifying the installation process.

Compatibility with other materials: Silicone heat-resistant gaskets have good compatibility with other materials (such as metal, plastic, etc.) and can be effectively combined with other components or materials.

Silicone heat-resistant gaskets are widely used in many industries, including automotive, aerospace, energy, electronics, food processing, and more. They provide high-temperature sealing, insulation and protection while improving equipment performance and reliability.

When selecting silicone heat-resistant gaskets, the selection should be based on the requirements of the specific application, such as required heat-resistant temperature range, chemical resistance, durability and size to ensure optimal performance and results.