矽膠水管

矽膠水管矽膠水管

矽膠水管矽膠水管

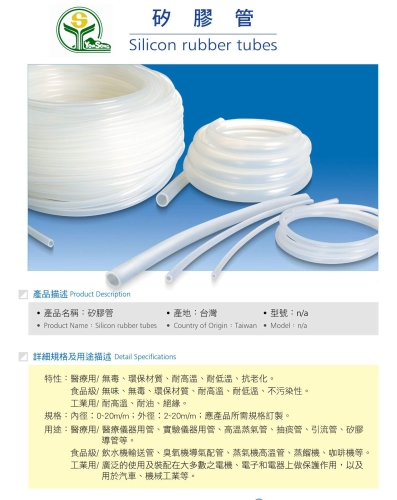

矽膠水管是使用矽膠材料製成的柔軟管道,用於輸送水或其他液體。它們通常具有矽膠的特性,如耐高溫、耐化學腐蝕和彈性。

矽膠水管的特點如下:

耐高溫性能:矽膠水管能夠承受高溫環境,通常耐溫範圍在-60°C至200°C之間。這使得它們適用於需要輸送高溫水或液體的應用。

耐化學腐蝕性:矽膠水管具有良好的耐化學腐蝕性能,能夠抵抗許多腐蝕性物質,如酸、鹼、油和溶劑。這使得它們在化學工業和實驗室應用中非常有用。

彈性和柔軟性:矽膠水管具有良好的彈性和柔軟性,能夠彎曲和扭轉而不損壞。這使得它們容易安裝和連接,並且適應各種複雜的管道布局。

無毒無味:矽膠水管通常是無毒無味的,符合食品級認證要求,可以安全地用於飲用水和食品加工等應用。

高透明度:某些矽膠水管具有高透明度,使得水流狀態可見,方便監測和檢查。

耐磨損性:矽膠水管具有優異的耐磨損性能,能夠抵抗機械磨損和壓力,提高使用壽命。

矽膠水管廣泛應用於食品和飲料業、醫療保健、實驗室、家用水淨化、工業設備等領域。選擇矽膠水管時,應根據具體的應用需求,考慮尺寸、耐溫範圍、耐壓能力、耐化學腐蝕性和安全認證等因素,以確保選擇適合的產品。

當選擇矽膠水管時,以下是一些進一步的考慮因素:

尺寸和內徑:確定所需的矽膠水管尺寸和內徑,以符合應用中的流量需求。考慮液體的流速和壓力,選擇適當尺寸的水管。

壁厚:矽膠水管的壁厚影響其耐壓能力和耐用性。根據應用需求和預期的壓力,選擇適當的壁厚。

耐壓能力:確保所選擇的矽膠水管能夠承受應用中的壓力要求。根據所需壓力和耐壓能力選擇適當的水管。

耐化學腐蝕性:考慮矽膠水管的耐化學腐蝕性能,特別是當接觸到化學物質時。確保水管能夠耐受應用中可能存在的化學品。

安全認證:確保所選擇的矽膠水管符合相關的安全和品質認證標準,如FDA認證(適用於食品接觸應用)或NSF認證(適用於飲用水應用)等。

耐久性和壽命:評估矽膠水管的耐久性和預期壽命,尤其是在長期使用和惡劣環境條件下。選擇具有良好耐久性和長壽命的矽膠水管可以減少維護和更換成本。

廠商和供應商:選擇可靠的矽膠水管製造商或供應商,以確保產品的質量和技術支援。研究評估不同廠商的信譽和客戶評價,選擇有良好口碑和信譽的供應商。

最後,確保正確的安裝和使用矽膠水管也是關鍵。遵循製造商提供的安裝指南和注意事項,確保水管獲得最佳的性能和壽命。

當選擇矽膠水管時,以下是更多的考慮因素:

彈性恢復時間:考慮矽膠水管的彈性恢復時間,即在應力消除後回復原狀的時間。這對於需要頻繁彎曲或變形的應用很重要,確保水管在使用後能夠迅速回復彈性,避免永久變形。

防滲漏性能:確保矽膠水管具有良好的防滲漏性能,特別是在高壓或高溫應用中。這可以防止液體或氣體的洩漏,確保系統的安全性和效能。

耐磨性:考慮矽膠水管的耐磨性能,特別是當水管需要經常接觸到固體表面或其他摩擦物時。耐磨性好的水管能夠提供更長的使用壽命。

擠出方式:矽膠水管可以通過不同的擠出方式製造,例如單層擠出、多層擠出和鑄造擠出等。不同的擠出方式可能會影響水管的特性和性能,需要根據具體應用需求選擇適當的擠出方式。

防黏連性:一些矽膠水管具有防黏連性能,即在接觸時不會黏在一起。這對於應用中需要多條水管靠近或接觸的場景很有用,避免不必要的阻塞和困難。

色彩選擇:矽膠水管通常有多種顏色可供選擇,如透明、白色、黑色等。根據應用需求,可以選擇適合的顏色。

維護和清潔:考慮矽膠水管的維護和清潔方式。一些水管可能需要定期清潔或特殊的保養方法,確保其持續的性能和衛生。

請記住,在選擇矽膠水管時,根據具體的應用需求和環境條件進行評估,並與製造商或供應商進一步溝通,以確保選擇最適合的產品。

耐高溫性:矽膠水管通常能夠承受高溫,因此在高溫水或液體輸送應用中非常有用。

彈性和柔軟性:它們具有優秀的彈性和柔軟性,能夠在彎曲和變形時保持其原始形狀。

耐化學腐蝕性:矽膠水管對許多化學品、藥劑和油類都有良好的耐腐蝕性,這使得它們適用於各種不同的化學環境。

食品安全:某些矽膠水管是食品級材料,可用於食品和飲料處理、包裝和分發。

高純度:矽膠水管通常具有高純度,無污染和無殘留物,因此在需要高純度的應用中很有價值,如半導體製造。

防滲透性:由於其柔軟性和密封性,矽膠水管能夠有效地防止液體滲漏。

耐候性:它們具有出色的耐候性,能夠長時間抵抗紫外線、氧氣和潮濕環境的影響。

電絕緣性:某些矽膠水管具有良好的電絕緣性能,可用於電子和電氣應用中。

醫療應用:矽膠水管也常用於醫療器械和醫療設備中,因其生物相容性和無毒性。

工業應用:在工業設備中,矽膠水管用於冷卻系統、化學處理、液體輸送等。

矽膠水管的這些特點使其在多個領域中都有廣泛的應用,包括食品業、醫療業、工業、建築、化學工業和電子等。無論是在哪個應用中,它們提供了可靠的管道解決方案,並且通常能夠滿足特定行業的要求和標準。

當談到矽膠水管時,還有一些其他方面和應用值得了解:

醫療和實驗室應用:矽膠水管常用於醫療設備、實驗室設備和醫療儀器中,包括血壓計、注射器、液體處理系統等。

高壓和真空系統:矽膠水管能夠應對高壓和真空系統中的需求,用於高壓氣體、真空工藝和實驗室設備。

汽車工業:在汽車工業中,矽膠水管用於冷卻系統、燃油系統、排氣系統和液壓系統。

飛機航空:在航空航天領域,矽膠水管用於飛機的油壓系統、燃油系統和氣壓系統中,以確保耐高壓和耐高溫性能。

油田和礦業:在油田和礦業應用中,矽膠水管用於油井注水、化學注入和礦山排放。

食品和飲料業:矽膠水管被廣泛用於食品和飲料業,用於輸送飲用水、食品原料和食品處理。

化學工業:在化學工業中,矽膠水管用於化學藥劑的儲存、運輸和處理。

環保應用:矽膠水管可用於環保設施中,用於處理廢水、廢水處理劑和氣體處理。

農業應用:在農業中,矽膠水管可用於灌溉系統、農藥處理和液體施肥。

液體輸送:矽膠水管可用於各種液體輸送應用,包括液體輸送管道、液體灌注和液體分發系統。

總的來說,矽膠水管是一種多功能性的管道材料,具有耐高溫、耐化學腐蝕、柔軟性和生物相容性等特點,因此廣泛應用於各種行業和應用領域。無論是在醫療、汽車、航空、化學、食品、環保還是其他領域,它們都發揮著重要的作用,並且通常符合行業標準和安全要求。

silicone water pipesilicon water pipes

Silicone water pipes are flexible pipes made of silicone material used to transport water or other liquids. They often share the properties of silicone, such as high temperature resistance, chemical resistance, and elasticity.

The characteristics of silicone water pipes are as follows:

High temperature resistance: Silicone water pipes can withstand high temperature environments, usually between -60°C and 200°C. This makes them suitable for applications where high temperature water or liquids need to be transported.

Chemical resistance: Silicone water pipes have good chemical resistance and can resist many corrosive substances, such as acids, alkalis, oils and solvents. This makes them very useful in chemical industry and laboratory applications.

Elasticity and softness: Silicone water pipes have good elasticity and softness and can be bent and twisted without damage. This makes them easy to install and connect, and adaptable to a variety of complex piping layouts.

Non-toxic and odorless: Silicone water pipes are generally non-toxic and odorless, meet food-grade certification requirements, and can be safely used in applications such as drinking water and food processing.

High transparency: Some silicone water pipes have high transparency, making the water flow status visible and convenient for monitoring and inspection.

Wear resistance: Silicone water pipes have excellent wear resistance and can resist mechanical wear and pressure, extending their service life.

Silicone water pipes are widely used in the food and beverage industry, healthcare, laboratories, household water purification, industrial equipment and other fields. When selecting silicone water pipes, factors such as size, temperature range, pressure resistance, chemical resistance, and safety certifications should be considered based on specific application needs to ensure that the appropriate product is selected.

When choosing silicone water pipes, here are some further considerations:

Size and ID: Determine the required size and ID of silicone water tubing to match the flow requirements in your application. Consider the flow rate and pressure of the liquid to select an appropriately sized water pipe.

Wall thickness: The wall thickness of a silicone water pipe affects its pressure resistance and durability. Select the appropriate wall thickness based on application needs and expected pressures.

Pressure resistance: Make sure the silicone water pipe you choose can withstand the pressure requirements of the application. Select the appropriate water pipe based on the required pressure and pressure resistance capabilities.

Chemical Resistance: Consider the chemical resistance of silicone water pipes, especially when exposed to chemicals. Make sure the water pipes can withstand the chemicals that may be present in the application.

Safety certification: Ensure that the selected silicone water pipe meets relevant safety and quality certification standards, such as FDA certification (for food contact applications) or NSF certification (for drinking water applications), etc.

Durability and Lifespan: Evaluate the durability and life expectancy of silicone water pipes, especially under long-term use and harsh environmental conditions. Choosing silicone water pipes with good durability and long life can reduce maintenance and replacement costs.

Manufacturers and Suppliers: Choose a reliable silicone water pipe manufacturer or supplier to ensure product quality and technical support. Research and evaluate the credibility and customer reviews of different vendors, and choose suppliers with good reputation and reputation.

Finally, ensuring proper installation and use of silicone hose is key. Follow the installation guidelines and precautions provided by the manufacturer to ensure optimal performance and longevity of your water pipes.

When choosing silicone water pipes, here are some more considerations:

Elastic recovery time: Consider the elastic recovery time of the silicone water pipe, that is, the time it takes to return to its original shape after the stress is relieved. This is important in applications that require frequent bending or deformation, ensuring that the water pipe can quickly regain its elasticity after use and avoid permanent deformation.

Anti-leak performance: Ensure that the silicone water pipe has good anti-leak performance, especially in high pressure or high temperature applications. This prevents leakage of liquid or gas, ensuring system safety and efficiency.

Wear resistance: Consider the wear resistance of silicone water pipes, especially when the water pipes need to be in frequent contact with solid surfaces or other friction objects. Water pipes with good wear resistance can provide longer service life.

Extrusion method: Silicone water pipes can be manufactured through different extrusion methods, such as single-layer extrusion, multi-layer extrusion, and cast extrusion. Different extrusion methods may affect the characteristics and performance of water pipes, and the appropriate extrusion method needs to be selected based on specific application requirements.

Anti-adhesion properties: Some silicone hoses are anti-adhesive, meaning they will not stick together on contact. This is useful for applications that require multiple water pipes to be close to or in contact with each other to avoid unnecessary blockage and difficulty.

Color selection: Silicone water pipes are usually available in a variety of colors, such as transparent, white, black, etc. Depending on the application requirements, the appropriate color can be selected.

Maintenance and Cleaning: Consider how your silicone water pipes are maintained and cleaned. Some water pipes may require regular cleaning or special maintenance methods to ensure their continued performance and hygiene.

Remember, when selecting silicone water pipes, evaluate based on specific application needs and environmental conditions, and further communicate with the manufacturer or supplier to ensure you select the most appropriate product.

High Temperature Resistance: Silicone water pipes are generally able to withstand high temperatures, making them useful in high-temperature water or liquid transfer applications.

Elasticity and Softness: They have excellent elasticity and softness, able to maintain their original shape when bent and deformed.

Chemical resistance: Silicone water pipes have good resistance to many chemicals, agents, and oils, making them suitable for use in a variety of chemical environments.

Food Safety: Some silicone water tubing is food grade and can be used for food and beverage handling, packaging and distribution.

High Purity: Silicone water tubing is typically high-purity, contamination-free, and residue-free, making it valuable in applications that require high purity, such as semiconductor manufacturing.

Anti-permeability: Due to its softness and sealing properties, silicone water pipes can effectively prevent liquid leakage.

Weather Resistance: They have excellent weather resistance and can withstand the effects of UV rays, oxygen and humid environments for a long time.

Electrical insulation: Some silicone water pipes have good electrical insulation properties and can be used in electronic and electrical applications.

Medical Applications: Silicone water tubing is also commonly used in medical devices and equipment due to its biocompatibility and non-toxicity.

Industrial Applications: In industrial equipment, silicone water pipes are used in cooling systems, chemical processing, liquid transportation, etc.

These characteristics of silicone water pipes make them widely used in many fields, including the food industry, medical industry, industry, construction, chemical industry and electronics. Regardless of the application, they provide reliable piping solutions and are often able to meet industry-specific requirements and standards.

When it comes to silicone water pipes, there are a few other aspects and applications worth knowing about:

Medical and Laboratory Applications: Silicone water tubing is commonly used in medical equipment, laboratory equipment, and medical instruments, including blood pressure monitors, syringes, liquid handling systems, and more.

High Pressure and Vacuum Systems: Silicone water tubing can handle the needs of high pressure and vacuum systems for use with high pressure gases, vacuum processes and laboratory equipment.

Automotive Industry: In the automotive industry, silicone water pipes are used in cooling systems, fuel systems, exhaust systems, and hydraulic systems.

Aircraft aviation: In the aerospace field, silicone water pipes are used in the oil pressure system, fuel system and pneumatic system of aircraft to ensure high pressure and high temperature resistance.

Oilfield and Mining: In oilfield and mining applications, silicone water tubing is used for well water injection, chemical injection, and mine drainage.

Food and Beverage Industry: Silicone water pipes are widely used in the food and beverage industry for conveying drinking water, food ingredients and food handling.

Chemical industry: In the chemical industry, silicone water pipes are used for the storage, transportation and handling of chemicals.

Environmental protection applications: Silicone water pipes can be used in environmental protection facilities for wastewater treatment, wastewater treatment agents and gas treatment.

Agricultural Applications: In agriculture, silicone water pipes are used in irrigation systems, pesticide treatment, and liquid fertilization.

Liquid transfer: Silicone water tubing can be used in a variety of liquid transfer applications, including liquid transfer piping, liquid perfusion, and liquid distribution systems.

In general, silicone water pipes are a versatile pipe material with the characteristics of high temperature resistance, chemical resistance, flexibility and biocompatibility, so they are widely used in various industries and applications. Whether in medical, automotive, aviation, chemical, food, environmental protection or other fields, they play an important role and usually comply with industry standards and safety requirements